In mechanical assembly and automotive repair, we often hear the old saying: "After tightening the bolt, turn it back half a turn." This may sound counterintuitive—why deliberately loosen it after going through the effort to tighten it? Is this just a piece of inherited "empirical folklore," or is there solid science behind it?

To understand the rationale behind the "half-turn back" operation, we first need to grasp the mechanical characteristics of bolted connections. During tightening, a bolt is not simply a rigid body; both the bolt and the connected components undergo elastic deformation.

Preload and Elastic Elongation:

When you tighten a bolt, it experiences tensile force and stretches slightly—like a spring being pulled. This force is known as preload, and it is crucial for ensuring a reliable connection, preventing loosening or separation. At the same time, the clamped workpieces (such as flanges or brackets) are compressed.

Yield Point and Interference from Friction:

During tightening, significant friction (including thread friction and friction between the bolt head and the surface of the connected part) consumes a large portion of the applied torque. Sometimes, when you feel that the torque has reached the specified value (i.e., it becomes harder to turn), the actual preload achieved by the bolt may still be below the optimal level, as part of the torque is "lost" to friction.

Purpose of the "Loosening" Operation:

Release Internal Stresses:

The main purpose of turning the bolt back half a turn is to release internal stresses and elastic deformations caused by friction and uneven loading. This slight reverse rotation allows the entire system—bolt, nut, and connected parts—to reach a new, more natural elastic equilibrium.

Redistribute the Load:

By loosening and then slightly retightening (sometimes followed by a small additional tightening, though not always necessary), the preload is distributed more evenly. This helps avoid localized high stress and makes the connection more stable and reliable.

In What Applications Is This "Half-Turn Back" Method Used?

Yield-Strength Bolts:

Some modern high-strength bolts are designed to be stretched slightly beyond their yield point during tightening (i.e., into the plastic deformation zone). For such bolts, turning back by a certain angle is part of the standard procedure. The goal is to eliminate torsional stress and ensure that the axial preload is more accurate and stable.

Soft or Composite Materials:

When the connected materials are relatively soft (e.g., aluminum alloys, plastics, certain composites, or when soft gaskets are involved), they may undergo noticeable creep or plastic deformation under pressure. Allowing the connection to sit for a while after tightening and then backing off slightly can compensate for preload loss due to material creep, helping maintain a stable connection.

Therefore, the "half-turn back" method is an empirical technique with specific applicable scenarios—it is not a universal rule.

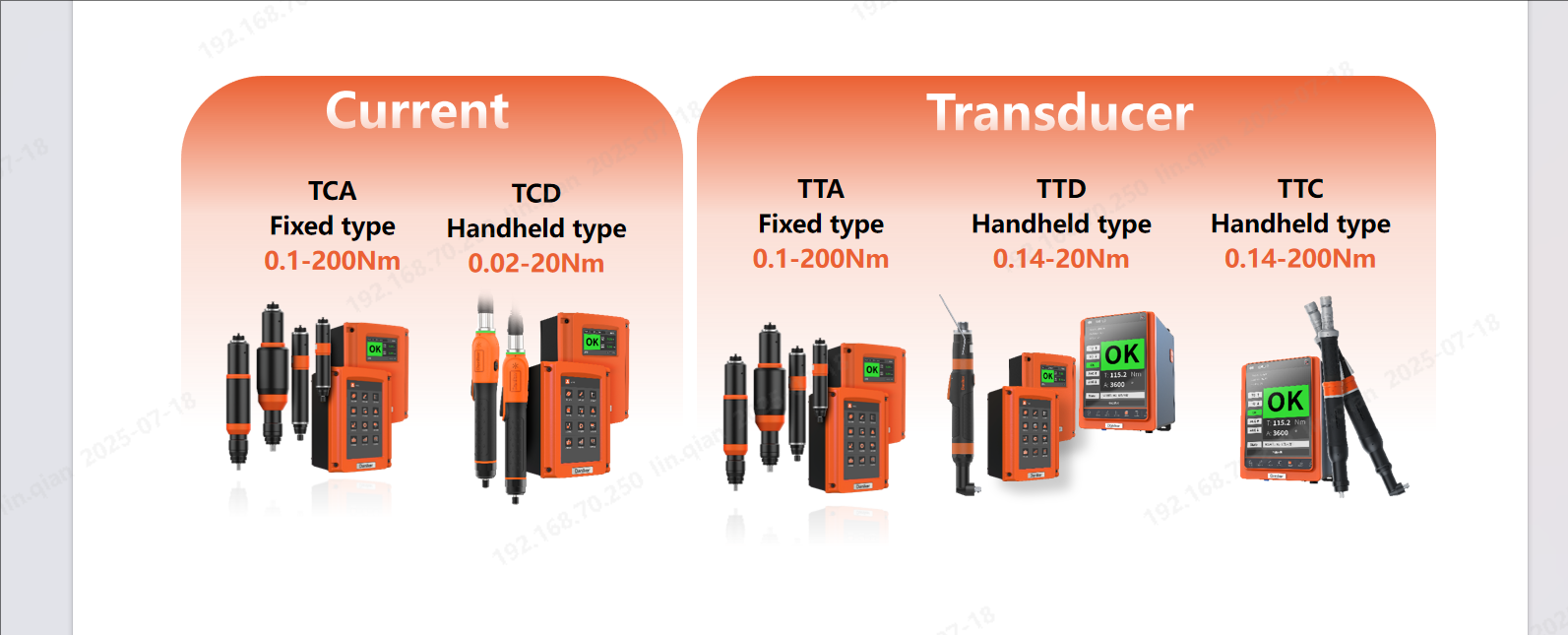

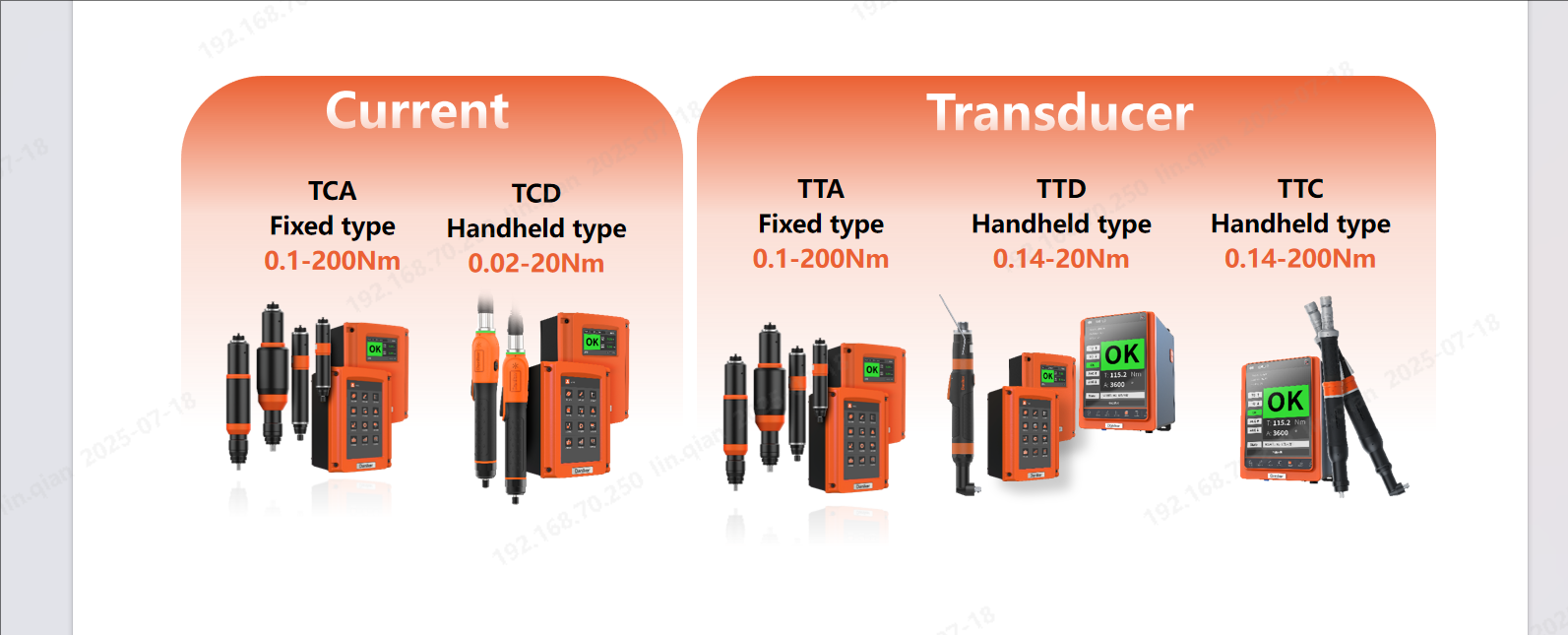

Danikor's intelligent electric screwdrivers offer a variety of tightening strategies, allowing precise control over torque and angle. During the tightening process, they can record and monitor data such as slope, torque, angle, and steps. The tightening curve is dynamically displayed, enabling early detection of issues like floating screws or thread stripping. These tools also feature data logging and storage functions, facilitating later traceability of each screw’s tightening status and providing strong data support for assembly quality control.