In automated production lines, O-type rubber rings, due to their soft material and easily adherable surfaces, often experience stacking during feeding. Stacking not only causes feeding interruptions and equipment jams but also significantly reduces the production pace, becoming a major bottleneck in automation efficiency. Flexible feeders, with their targeted technical design and multi-dimensional coordinated control, can effectively solve this problem, providing a stable and reliable solution for feeding materials prone to stacking.

I. Quantitative Supplement Control: Preventing Excessive Material Accumulation from the Source

The root of stacking issues often lies in the supplement process. Excessive materials accumulating in the tray can easily form hard-to-disperse stacks due to compression and friction. Flexible feeders adopt a "small amounts, multiple times" quantitative control principle in the supplement system design, strictly controlling the amount of material supplemented each time through a material counting module and a supplement trigger mechanism.

Specifically, the system automatically adjusts the supplement frequency based on the real-time material remaining in the tray. When the material decreases to a set threshold, the supplement mechanism releases a measured amount of material, ensuring a reasonable stock of material is always maintained in the tray. This control method can prevent feeding interruptions caused by insufficient material and also prevent stacking issues caused by excessive accumulation from the source, laying a foundation for subsequent material dispersion.

II. Automatic Frequency Finding + Intelligent Amplitude Stabilization: Dynamic Adaptation to Achieve Dispersion Effect

The adaptability of vibration parameters is a core factor in determining whether materials can be effectively dispersed. There are subtle differences in the weight and elasticity coefficient of O-type rubber rings, and fixed vibration frequencies and amplitudes are hard to adapt to all material states, making it easy for some materials to remain stacked. The "automatic frequency finding" and "intelligent amplitude stabilization" functions equipped on flexible feeders can dynamically optimize vibration parameters to achieve targeted dispersion.

The automatic frequency finding function captures real-time material vibration feedback data through built-in sensors, quickly analyzes and locks onto the resonant frequency that can disperse the materials, ensuring that vibration energy acts on the materials. The intelligent amplitude stabilization function adaptively adjusts the amplitude size based on the change in material remaining in the tray—when there is more material, it appropriately increases the amplitude to enhance dispersion force, and when there is less material, it reduces the amplitude to avoid excessive vibration causing material splash. The synergistic effect of these two functions ensures that materials remain evenly dispersed during the feeding process, fundamentally reducing stacking.

III. Anti-Static Tray Selection: Solving Stacking Hidden Dangers Caused by Material Adhesion

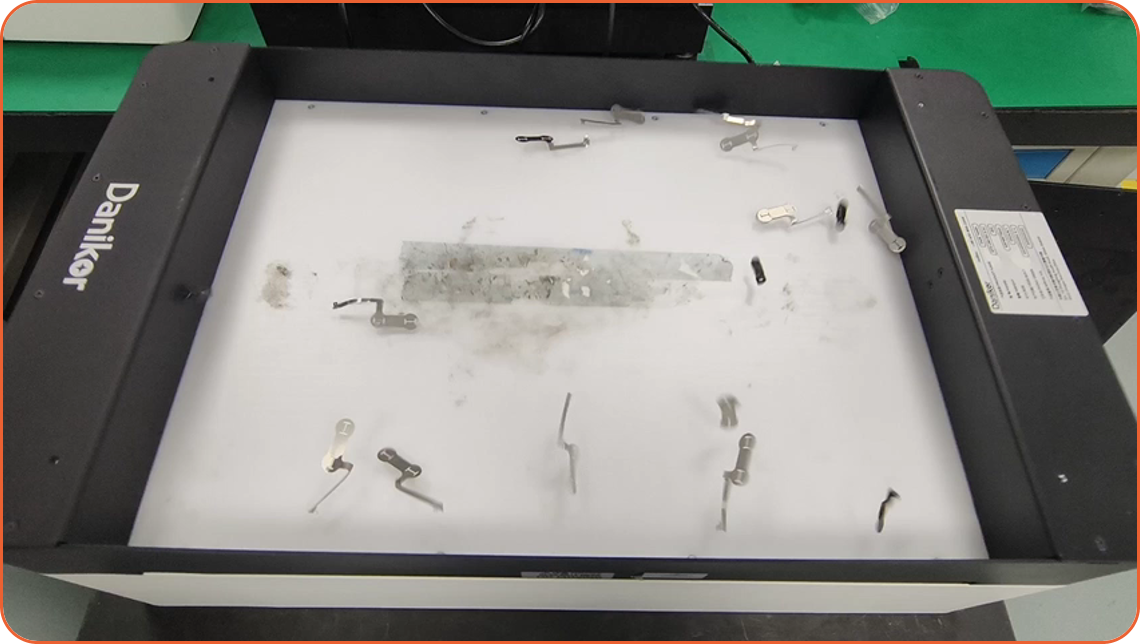

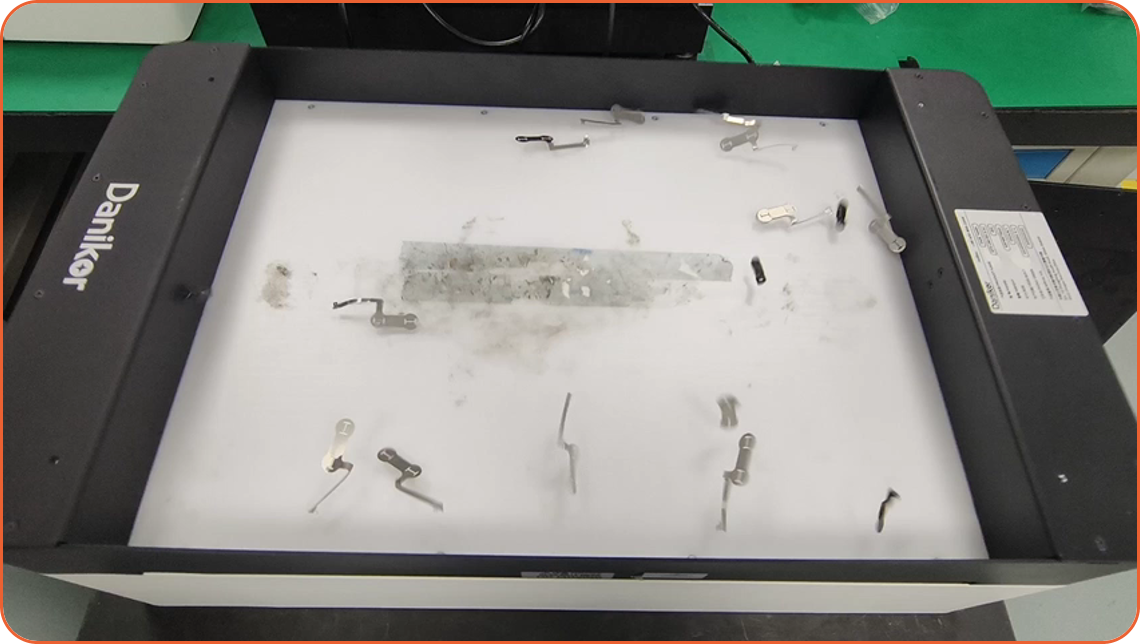

O-type rubber rings are polymer materials, which are prone to generate static electricity during the vibration process due to friction. Static electricity adhesion can cause materials to stick to each other, forming tightly stacked "material clumps" that are hard to disperse with conventional vibration. In response to this characteristic, flexible feeders can be equipped with special anti-static trays, eliminating the hidden danger of static electricity adhesion from the material level.

Anti-static trays are made of composite materials with excellent electrical conductivity, which can quickly conduct the static electricity generated by the materials into the grounding system, effectively reducing the static voltage on the material surface. At the same time, the inner wall of the tray is specially treated to reduce the friction coefficient with rubber materials, further reducing static electricity generation and material adhesion. Through the application of anti-static trays, the probability of stacking caused by material characteristics can be significantly reduced, ensuring that materials always remain in an independent and dispersed state.

Flexible feeders provide an effective anti-stacking solution for O-type rubber rings and other materials prone to stacking through a multi-dimensional technical combination of "quantitative supplement control + automatic frequency finding and stabilization + anti-static trays." This solution not only reduces downtime in the feeding process and improves the overall production line pace but also lowers manual intervention costs, providing strong support for the stability and convenience of automated production. In fields such as precision manufacturing, automotive parts, and electronic components, where high precision in material feeding is required, the anti-stacking technology of flexible feeders is becoming a key force in improving production efficiency.